Aerospace Engineering

The department of Aerospace Engineering, acquired from the Austrian Institute of Technology in 2010, has more than 30 years of experience in the support of space-related technology developments. The international team, consisting of experts from different fields, regularly supplies the European space industry with innovative technology solutions, such as electrical and chemical propulsion technologies and energy systems.

Over the past 30 years, these technologies have been distributed throughout our solar system. They can be found everywhere from low earth orbit to comet 67P/Churyumov-Gerasimenko (Rosetta).

These technologies have contributed to the success of missions such as Geotail, Equator-S, Cluster, Cluster-II, Rosetta, DoubleStar and MMS.

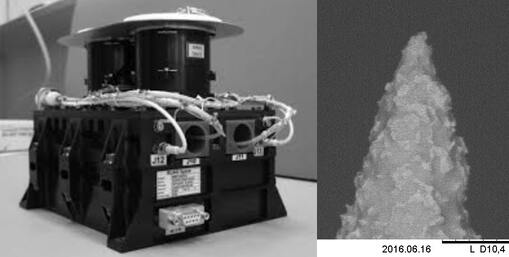

ION EMITTER

FOTEC is the only supplier worldwide who can offer space qualified liquid metal ion sources. These ion sources are used for mass spectrometers on missions such as Rosetta and for spacecraft potential control on missions such as Cluster II.

Several ion emitter technologies are available including solid needles, capillaries and porous needles.

Together with our partners, we offer flight proven Active Spacecraft Potential Control (ASPOC) devices, for example on the NASA MMS constellation.

Download info brochure

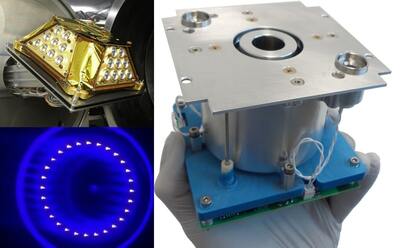

ELECTRIC PROPULSION

FOTEC is developing high accuracy electric propulsion technologies to enable formation flying and for drag compensation of spacecrafts. High performance thrust modules are under development for science missions such as NGGM, LISA and Darwin. From this technology, a commercial product has been derived: the IFM Nano Thruster. This thruster is a very competitive propulsion system for small satellites. In 2017 the system will be demonstrated in space for the first time. For more information about this product visit www.enpulsion.com

Download info brochure

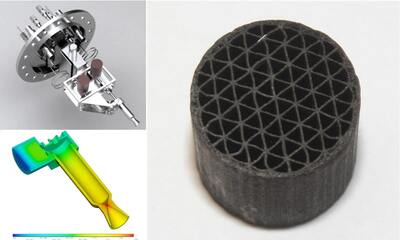

CHEMICAL PROPULSION

FOTEC is strongly involved in developing green propulsion system technologies as an alternative to those based on hydrazine.

The chemical propulsion team is developing green, hydrogen peroxide based bi-propellant thrusters for attitude and orbit control systems of satellites. Typical thrust levels are in the range from 1 to 20 N.

These activities include the development of catalysts required for decomposition of the propellant, injectors for bi-propellant thrusters and small-scale combustion systems as well as compatibility studies of propellants with typical construction materials.

The required expertise for this, such as the understanding of the thermal behaviour and combustion processes, is regularly used for terrestrial applications.

Download info brochure

TESTING SERVICES

- Direct thrust measurements (µN to mN)

- Plume characterization

- Lifetime testing

- Vibration

- Shock

- Thermal vacuum

- Thermal cycling

LAB EQUIPMENT

- Several smaller vacuum chambers (from 10 dm3 to 1.3 m3) for component development

- 4 medium-sized vacuum chambers (~3 m3) for the development and characterization of propulsion systems

- Large vacuum chamber (~14 m3) for plasma diagnostics including class-7 cleanroom tent

- Large vacuum chamber (~14 m3) for thermal vacuum tests including class-7 cleanroom tent

- Test facility for chemical propulsion systems

- Facilities for environmental tests (vibration test stand, shock table, thermal vacuum tests)

- Cleanroom class-7 for assembly and test preparations

- Chemical laboratory

QUESTION(S)?

GET IN CONTACT WITH US

Dr. Bernhard Seifert BSc

Head of the Aerospace Engineering Department

Tel.: +43 5 0421 8400

E-Mail: seifert@fotec.at